Rear shock absorbers change:

This Brico explains how to change the rear shocks on a Mini Cooper S JCW late 2003.

The first thing to do is to lift and support the car properly. In this case I picked up the car with your cat from the heel elevation that is in the lower front of the car. I did this because I take the taco rear elevation to fit the car. It may fit solid wood blocks (I did so). Once back road car, go down the drive from the front anchor where we have a cat, and we see that the rear wheel on one side and left the air. We took the cat and do the same operation on the other side and we will have the two rear wheels raised and ready to be disassembled.

The second step is to remove the rear wheels of the car to have good access to the screws holding the rear shocks.

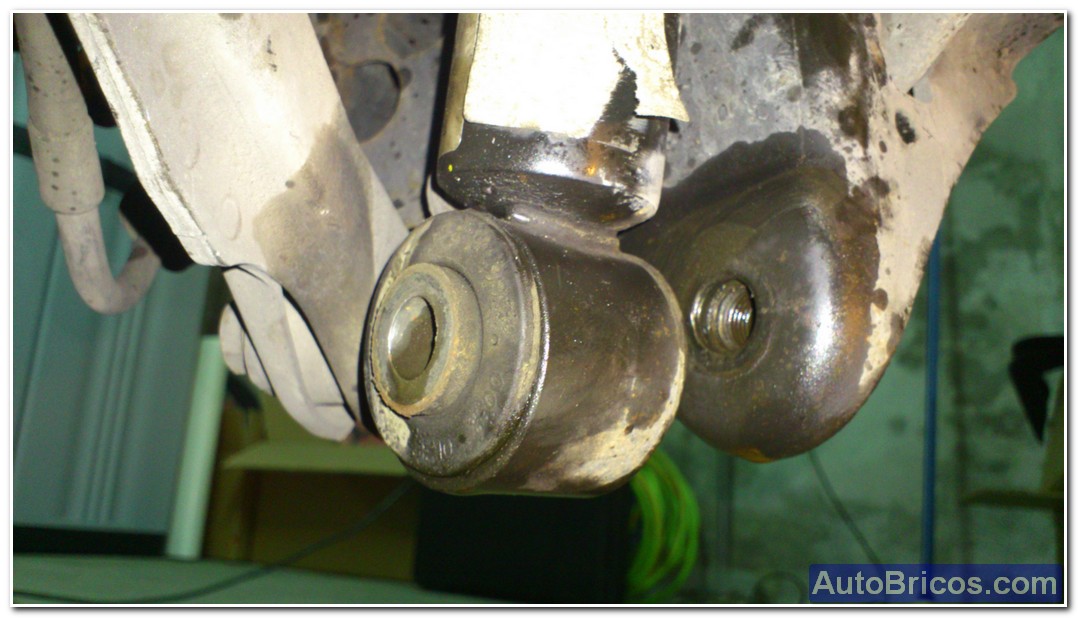

Once done, start drawing a rubber that has the rear shock right in the lower anchor. That will set the screw anchors the bottom of the shock.

|

|

To get good advise him that screw with 3in1 or WD40 type lubricant and let it "marinate" a few minutes because the thread can be oxidized by the passage of time, and is a large screw, so worth it.

|

|

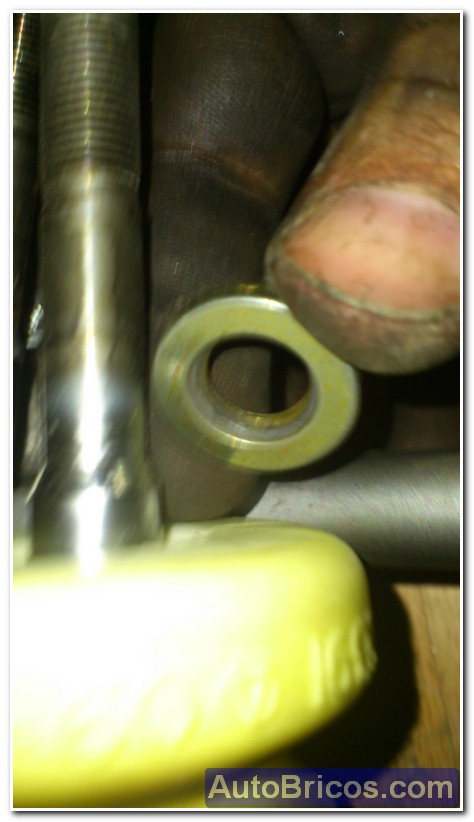

To unscrew I used a socket wrench with a handle of half inch and an additional tube for a little more leverage, because in my case was durillo, but went right after an intense struggle. If we look closely, has a triangular washer, this washer is the anchor of the rubber protector that we have taken at the very beginning.

|

|

Once removed the lower screw can already draw the 2 hexagon screws that secure the chassis damping turret. Note that you have to unpin the brake hose and ABS sensor cable from its receptacle. They come out easily.

|

|

|

In this case I shall replace the original shock absorbers for about Monroe Reflex. In the next picture you can see the top of the turret buffer.

|

|

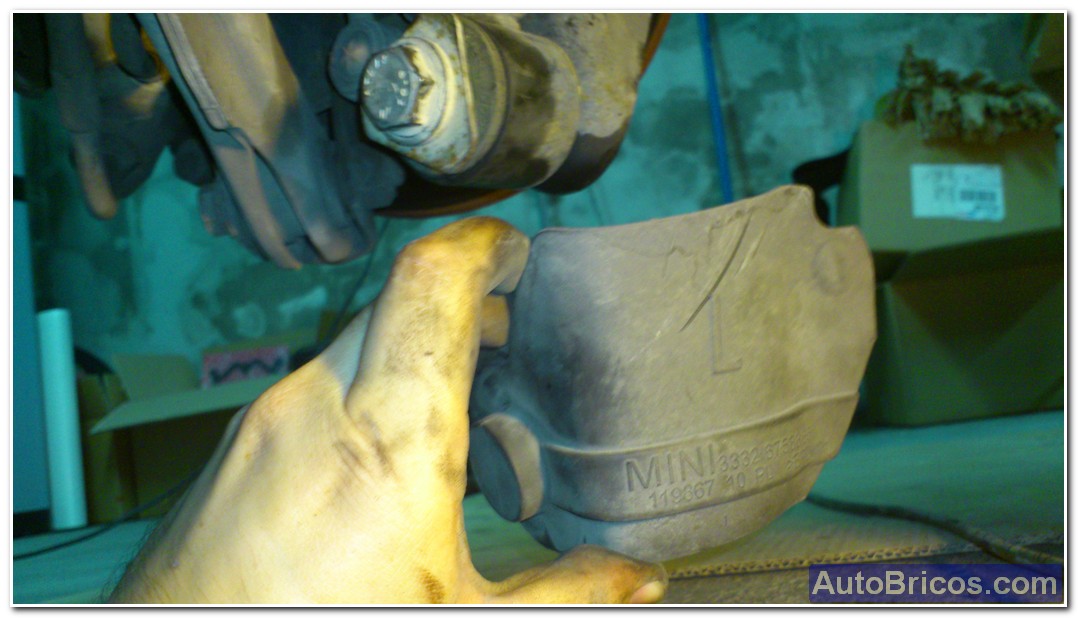

I thought the left and right dampers were different, but it turns out they are exactly the same parts and could be exchanged seamlessly.The originals do have some differences in the deck that are anchored brake hose and ABS sensor. Also have different coded in the factory.

|

|

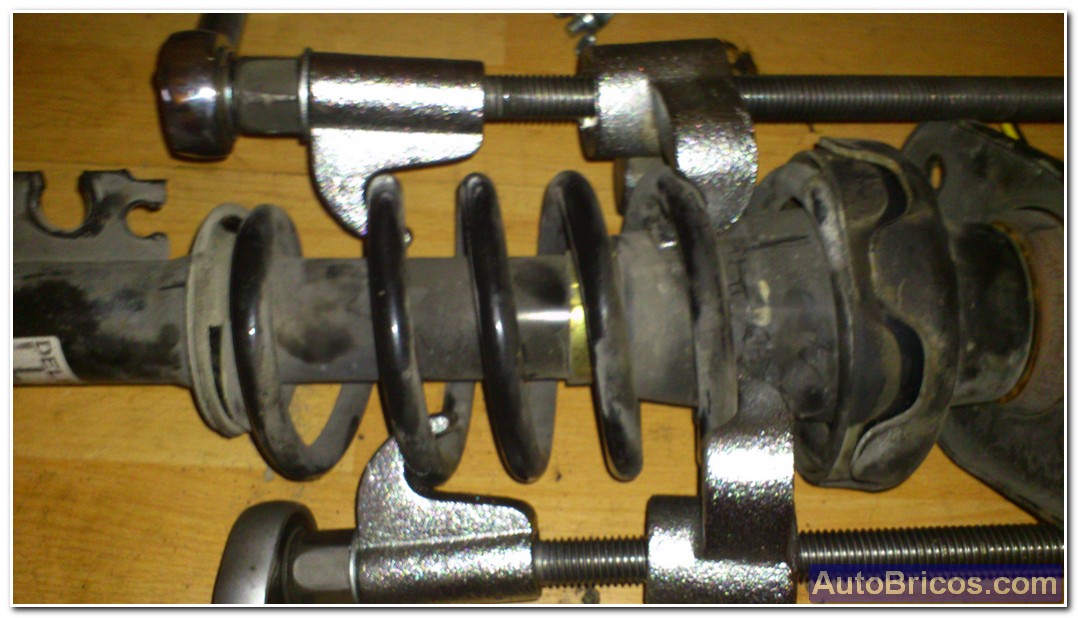

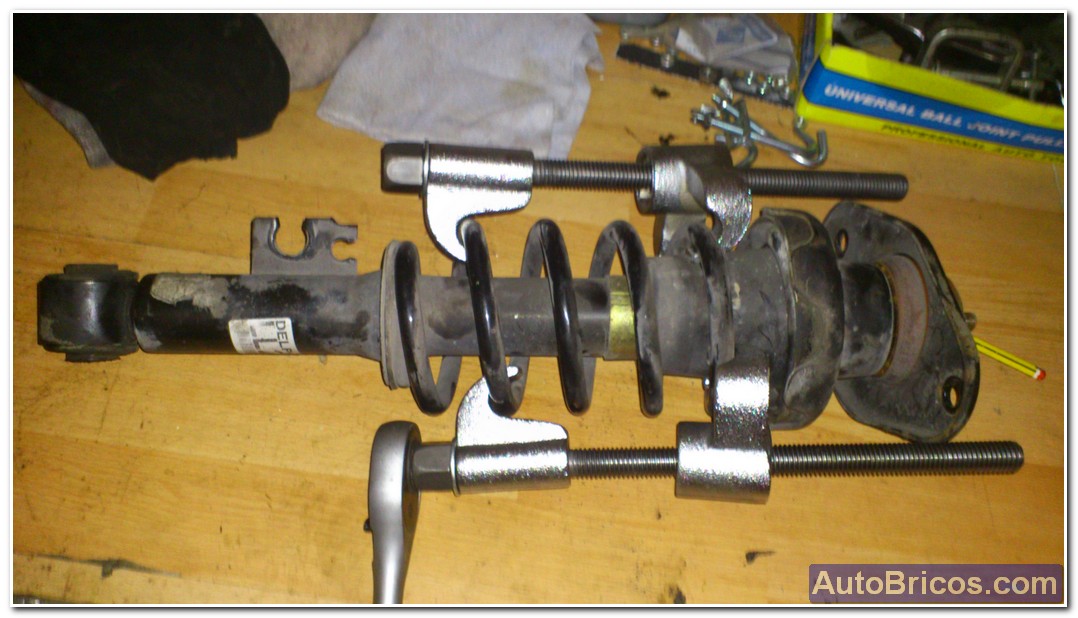

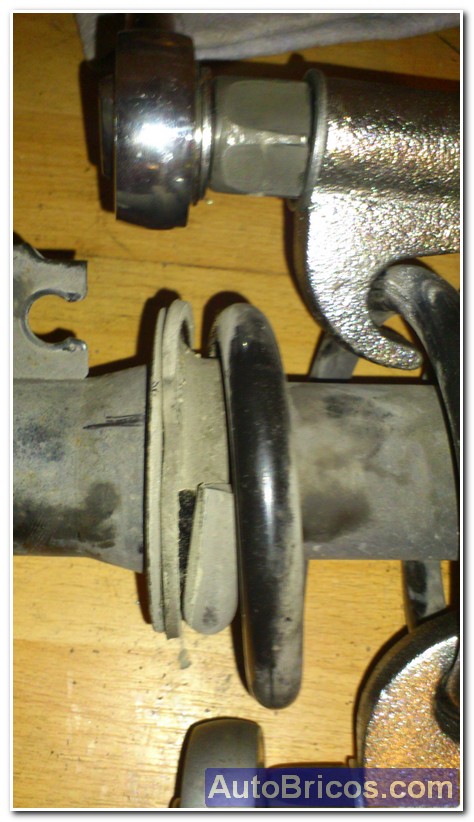

With damping turret either, we have to compress the spring to release the pressure between the upper and lower cup, and unwind with the female security top damper. Must be used for this purpose a spring compressor that is appropriately sized so that they are well anchored staples and to work safely. The force to compress the spring is very large, so you have to be very careful to avoid unnecessary risks.

We will know the pressure is released in the cups when the spring begins to move freely between the cups, we see that the tires are going peeling off the cups and pier.

|

|

The first photo shows the bottom plate and the spring as you lift the rubber support. In the second photo shows the top plate and also be seen to be taking off the rubber cup.

|

|

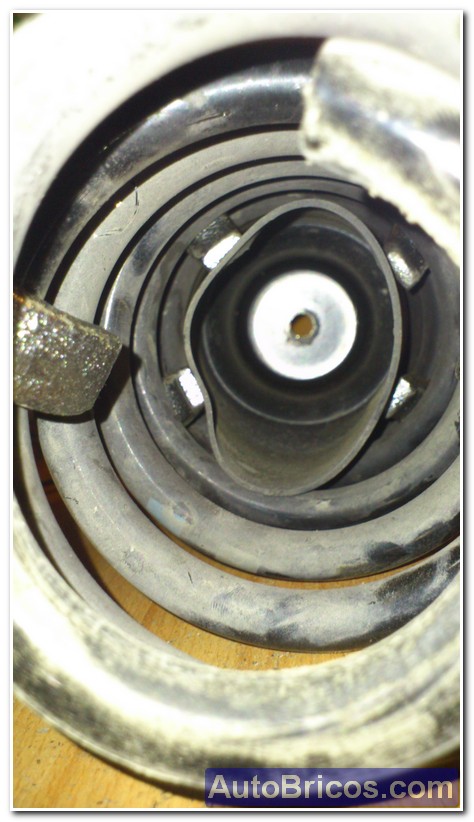

Once we see that the dock is fully released and that no pressure is exerted between cups, we can remove the upper shock nut to remove.Pay attention to the order and position of the parts is very important. Note that there is a washer with inner countersink has position.

|

|

|

Once removed the old shocks, and can be mounted new shocks following the reverse process.

Observe the color coding of the spring. Depending on the version of Mini (One, Cooper, Cooper S) are different encodings, and I have understood that according to the hardness change this color coding. Shocks may also change depending on the version of car, and yours is that shock and spring go accordingly.

|

|

Here you can see the old shocks (they are the original Mini Cooper S), and in the last picture you can already see the new turret placed cushioning.

|

|

Advise torques follow manufacturer's suggested there technical manuals for the network that facilitate them.

| Tweet |

Oil service interval reset Audi A4 B8

Oil service interval reset Audi A4 B8